Rubber O-Rings

Rubber O-rings are the most common sealing product in the world!

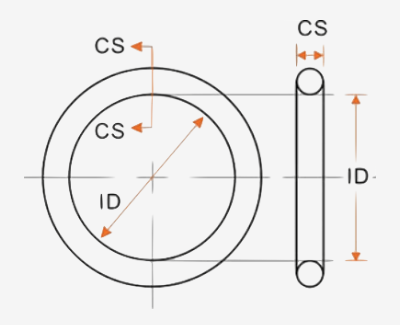

A rubber O-ring is a toroidal seal with a circular cross section, made from a variety of elastomers. Used effectively, an O-ring can seal practically all fluids, both liquid and gas.

Some plasmas too!